The 2022 LED Strip Lights Types Definitive Guide

LED strip lights becomes very popular in the recent years. You could use LED strip lights as cove lighting, or direct linear light.

It's most possible that this article would help solving all your questions.

We classify almost all led strip lighting by many different ways, and giving all pros & cons of each one. You might feel crystal after reading. Let's get start.

LED strip light classifications

Firstly, we are going to classify all the led strip lights by the following specifications:

1. by SMD types of LED chips

2. by outer sealing materials

3. by Input voltage

4. by LED colors

5. by controlling

6. by apparent shapes

by SMD types of LED chips

SMD5050 led strips

SMD2835 led strips

SMD3014 led strips

SMD3528 led strips

SMD3528 is the elder brother of SMD3014 & SMD2835. It got bigger sizes than SMD2835, but with lower power, around 0.1W per chips. It becomes out of market during the popular of SMD2835.

SMD5730/5630 led strips

5730 & 5630 are nearly the same format without significant difference. This size of LED chips got high power (0.5-1W, typical 0.5W) and brightness, with the advantage of large size. It is not common in the usage of LED strip light. However, it was quite common used in High Voltage LED strips.

COB Strip lights

By the apparent sealing materials

Raw Strips

Substrates, LED chips, resistants, and connecting cables, sometimes with back tape, that are all the necessary parts of the strips light. This is the basic type of LED strips, we called it Raw Strips. Even you can see the soldering pads and also you can touch them. However, thanks to the low voltage design, it's still very safe to use this raw strips.

Half-irrigation Strips

Full-irrigation Strips

PVC Strip

Silicon Pipe Strip

- More stable, even in severe chemical applications

- resist to high temperature,

- anti-aging, will not muddy during long time usage,

- waterproof, excellent insulation resistance.

Silicon Strip

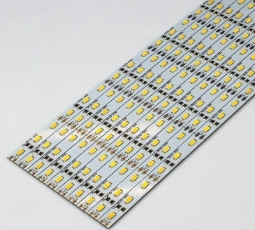

Hard Substrate LED Strip

Aluminum Profile Strip Lights

We will continue to introduce the rest classifications in the next blogs. keep updated by subscribe to our newsletters now.